What You Should Know About API 16A BOP Stacks for Drilling Rigs

In the realm of oil and natural gas drilling, safety is always of paramount importance. To ensure the safety of drilling operations, BOP Stacks are a critical component used to control wellhead pressure and prevent blowout incidents. When manufacturing BOP Stacks, we generally adhere to the specifications of API 16A. Today, Sino Mechanical wishes to delve into the fundamental concepts of BOP Stacks, understand their components, and learn how to select the right BOP stack that suits your needs.

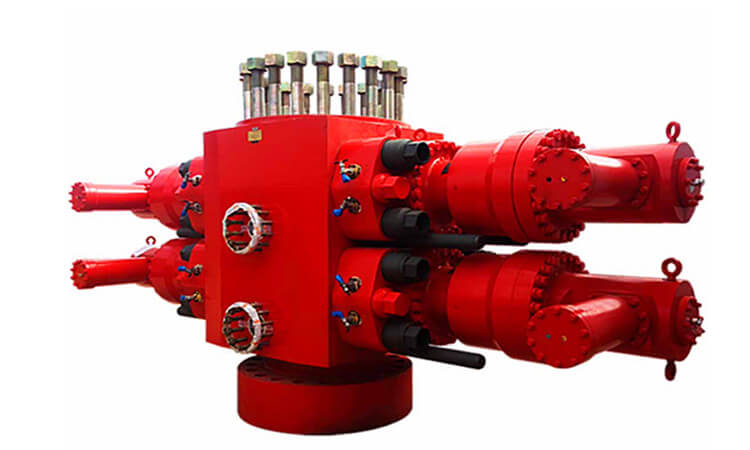

What are BOP Stacks?

API 16A BOP Stacks are essential safety devices designed for use in oil and natural gas drilling rigs. They are composite systems created to control wellhead pressure and, in case of emergencies, shut off the wellhead to prevent hazardous blowout incidents. Whether onshore or offshore drilling, BOP Stacks are integral components safeguarding both personnel and equipment.

What Components Make Up BOP Stacks?

BOP Stacks consist of several vital components, including:

Blowout Preventer (BOP): Typically encompassing annular BOPs and ram BOPs used for sealing the wellbore.

Control System: Used for operating and controlling the BOP, including hydraulic systems and control panels.

Emergency Shear Rams: Employed for cutting off wellhead tubulars in response to emergencies.

Kill and Choke Manifold: Regulating wellhead pressure and wellbore conditions.

Wellhead Connections: Interfacing with the wellhead tree to ensure secure well closure and prevent leaks.

Safety Valves: Releasing pressure to prevent blowout incidents.

Capping Stacks: Ensuring safe wellhead closure.

Control Oil System: Providing the necessary hydraulic pressure and flow for operation.

These components work together to guarantee the safety and efficiency of drilling operations.

How to Choose the Right BOP Stacks?

Selecting the appropriate BOP stack is of utmost importance. Factors to consider include model, size, working pressure, environmental conditions, and compliance. Ensure that the BOP stack adheres to API 16A standards, a crucial aspect in ensuring safety and reliability. Additionally, consult with professionals to ensure that the chosen BOP stack meets specific project requirements.

As a supplier, Sino Mechanical offers BOP Stacks of exceptional quality and performance, ensuring maximum reliability for our customers. Our products adhere to API 16A standards, guaranteeing their safety and compliance. We provide customized BOP Stacks to meet the specific needs of our customers. When choosing a BOP stack supplier, Sino Mechanical is a reliable partner well worth considering.

评论

发表评论